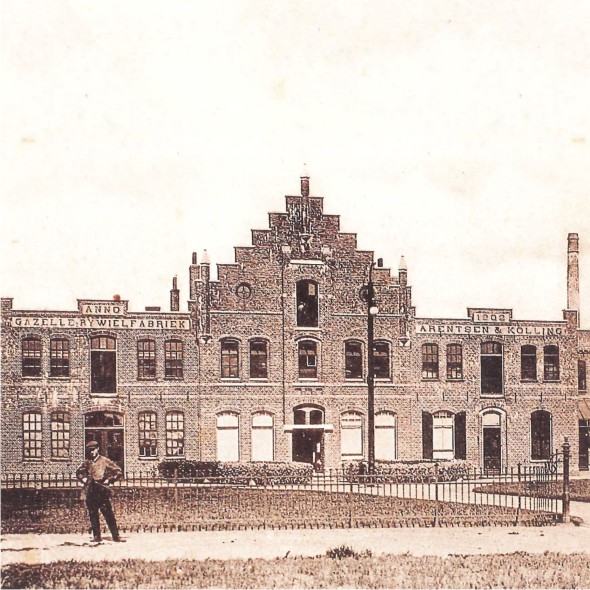

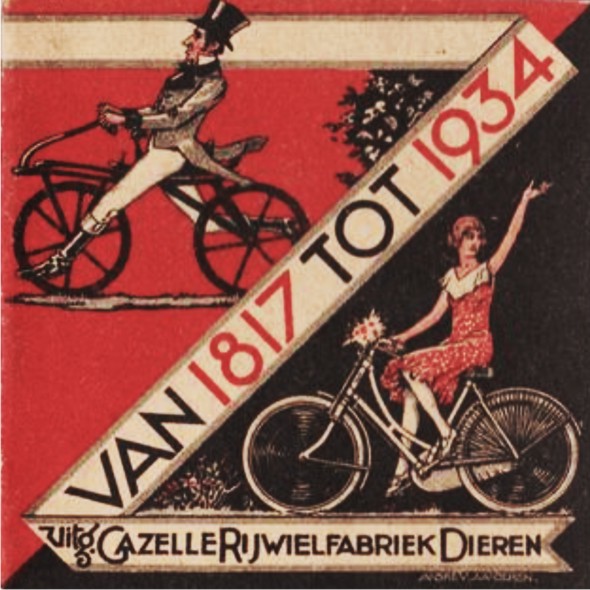

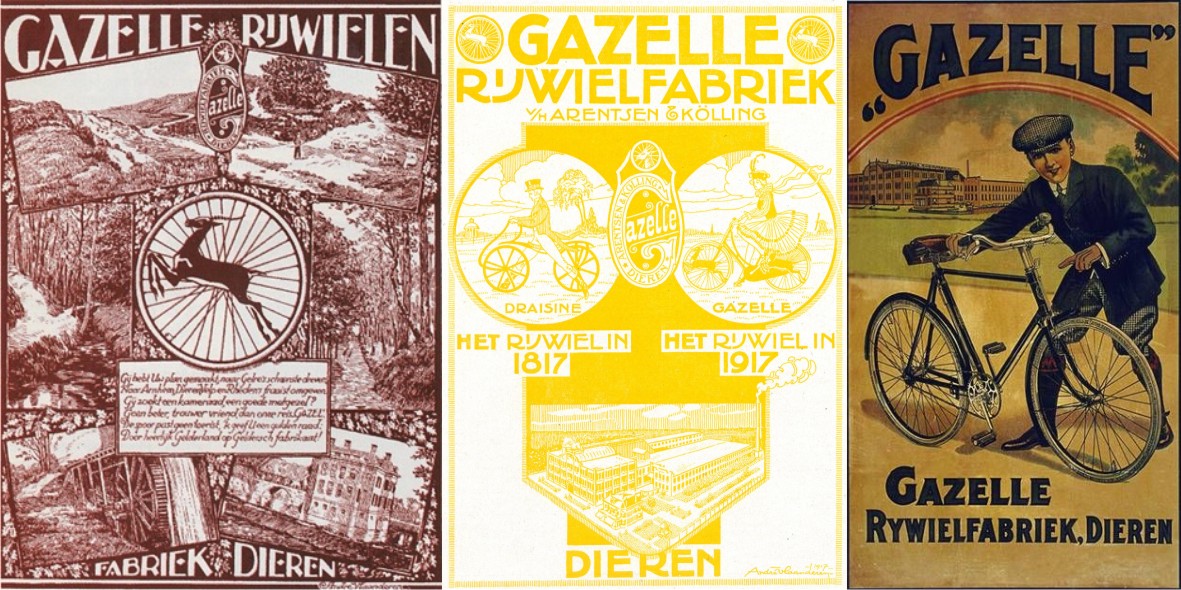

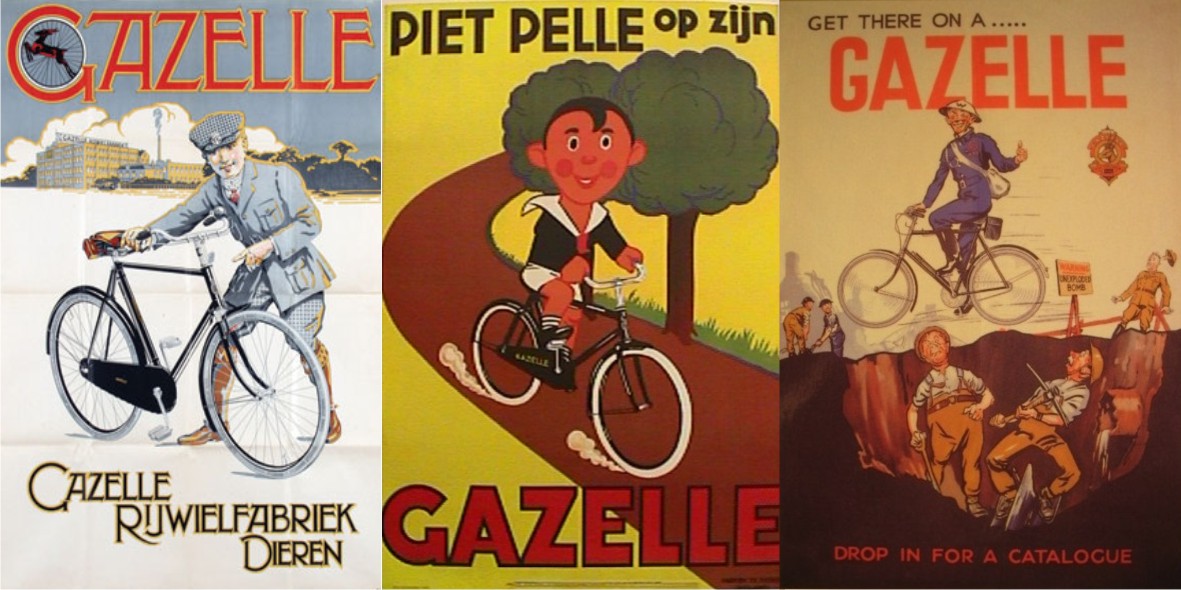

1892

WILLEM KÖLLING

postal worker in a Dutch village

DIEREN

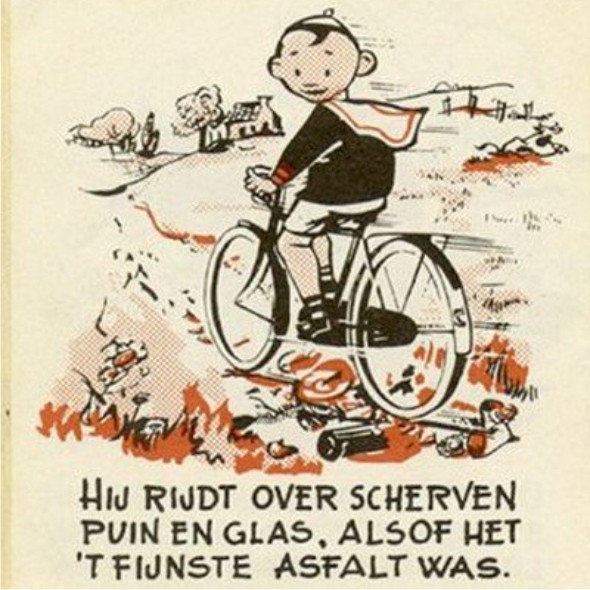

decided to engage in bicycle trade, as one of the first noticing the advantages of this new vehicle. Initially, Kölling sold bicycles imported from England. Soon, he established cooperation with a seller in a hardware store

RUDOLFEM ARENTZENEM

1902

The partners bought new rooms and started their own production under the name

GAZELLE

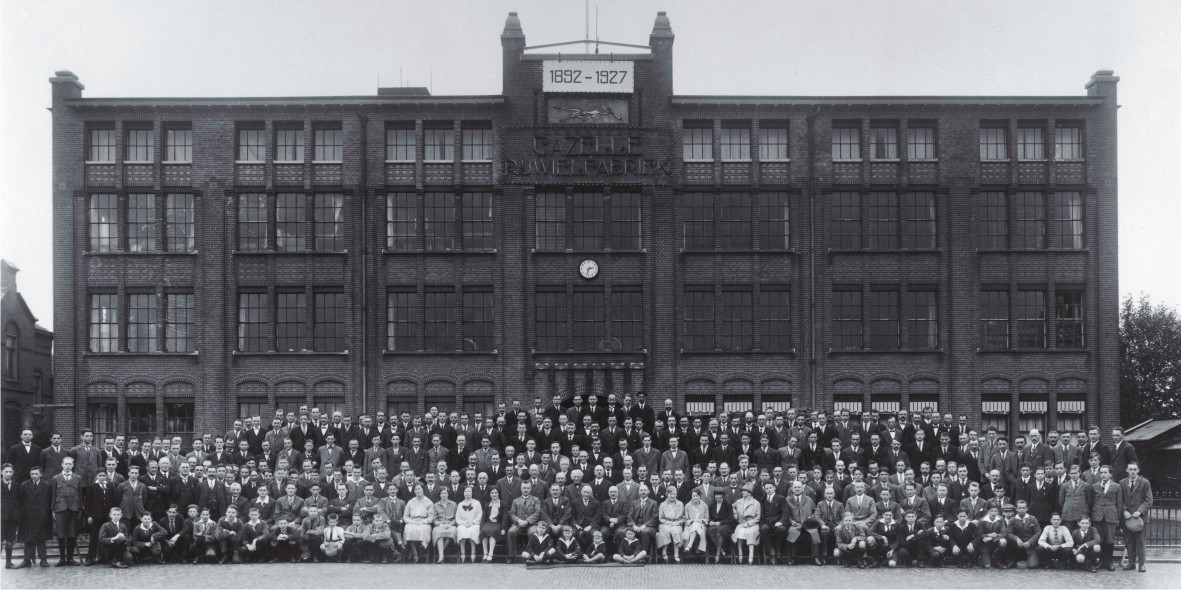

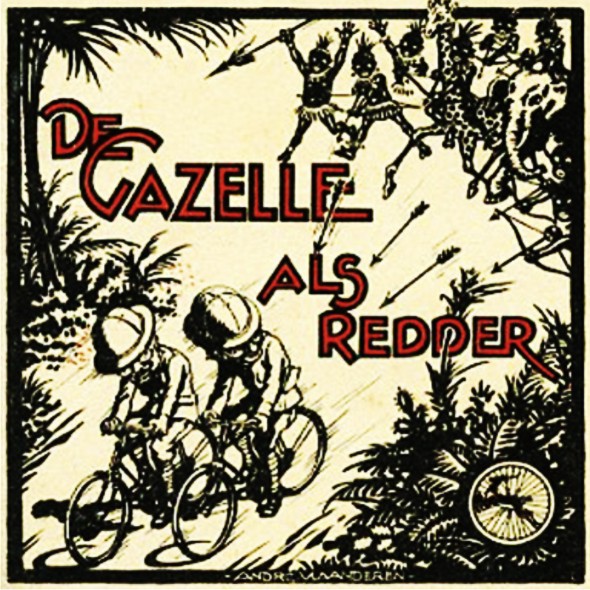

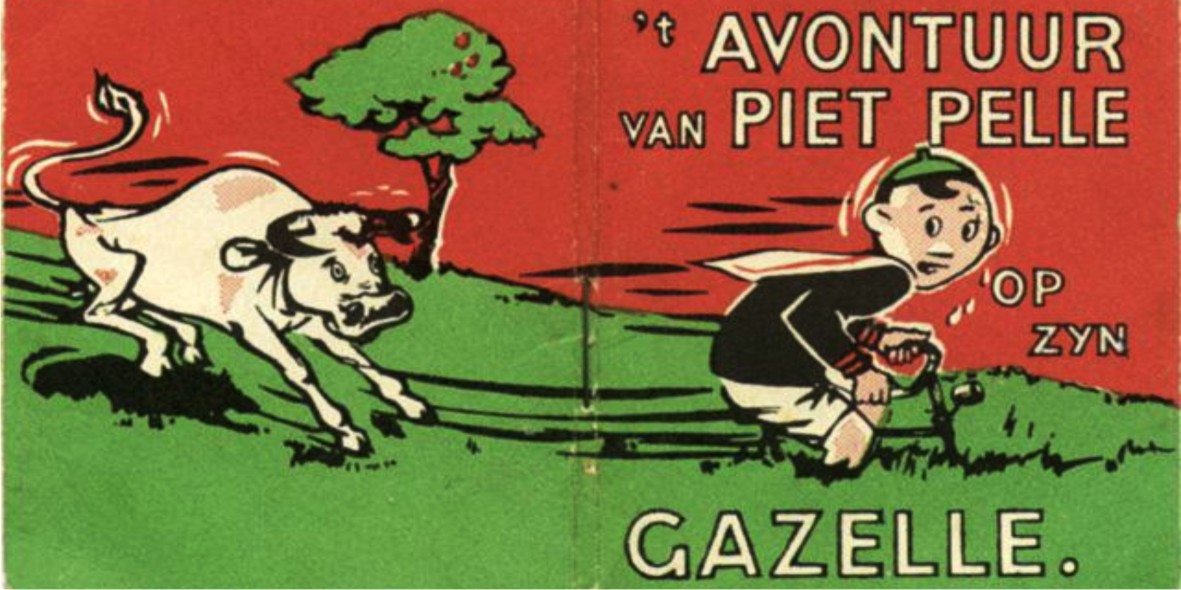

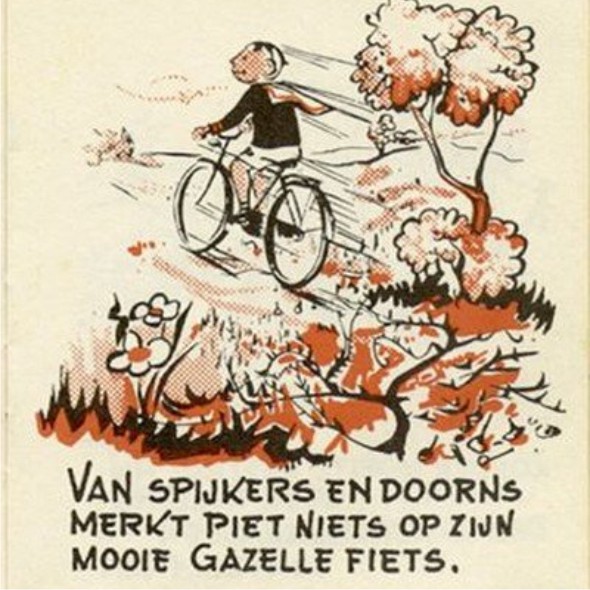

1920-1940

In the years 1920-1940 the company was constantly growing. The domestic market as well as international demand are constantly increasing. This is also due to the growing market for Gazelle bicycles in Indonesia, which was a Dutch colony at the time. Many Gazelle bikes have survived throughout Indonesia to this day and are items sought after by collectors.

1935

The Gazelle company introduces

THE FIRST TANDEM

very popular in the years before World War II. In the year of its introduction

600 TANDEMS

SOLD ONCE

1937

The company produces

THE FIRST ELECTRIC BIKE

designed by Philips, powered by a 12V battery.

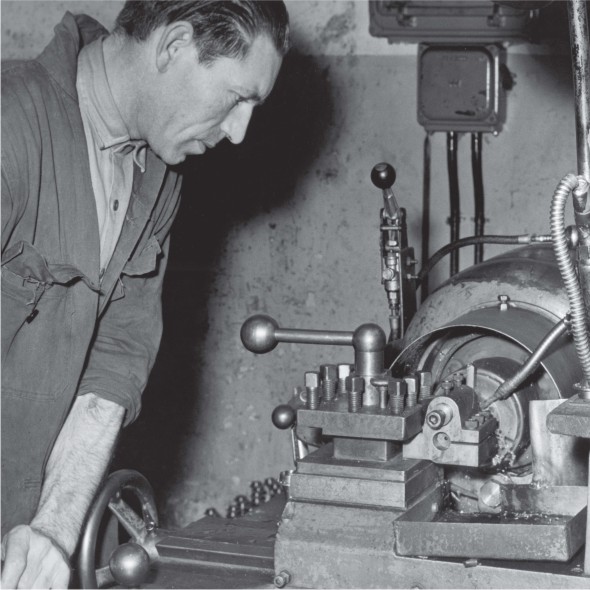

A TIME OF WAR

Like many other Dutch companies, war is a difficult period for Gazelle. Most of the factory equipment is dismantled by the German occupier and transported to Germany.

Other machines were blown up just before the Allies arrived.

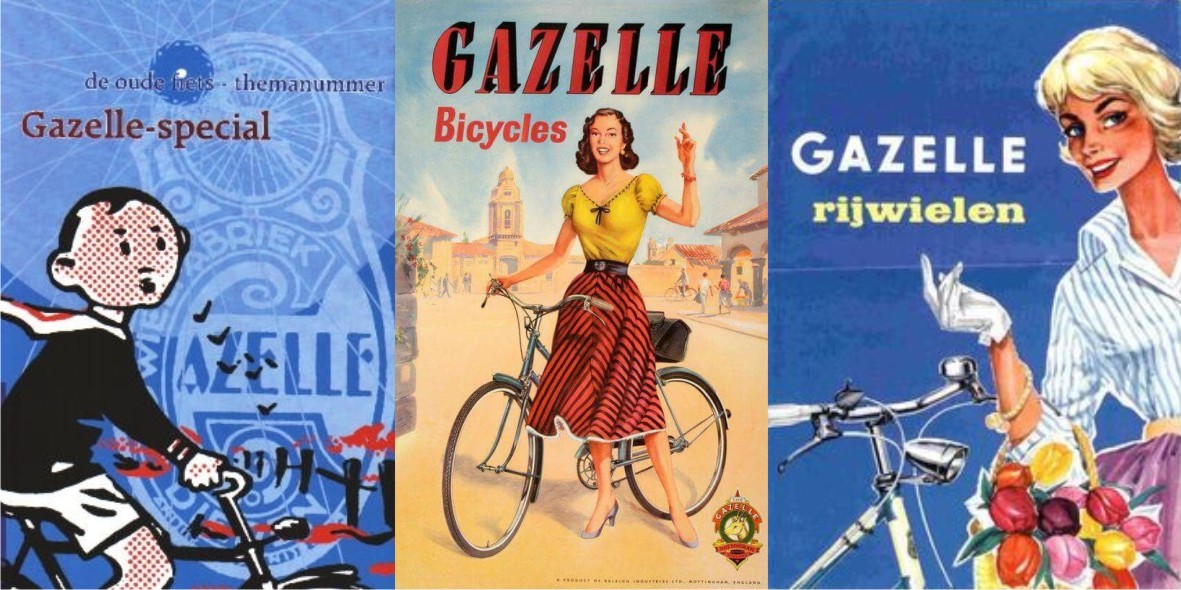

1946

Is available

FIRST

POST-WAR BIKE

GAZELLE

1954

Gazelle became a public company and produced a millionth bicycle.

1.000.000

bike!

1959

Gazelle patenteeritud

FIRST

3-KIIRE HUB

1960

Gazelle creates bikes that in addition

DRUM BRAKE

in the front hub have

3-SPEED REAR HUB

WITH DRUM BRAKE,

which are still in production today. However, after releasing approximately 45-50 thousand copies were discontinued due to high costs.

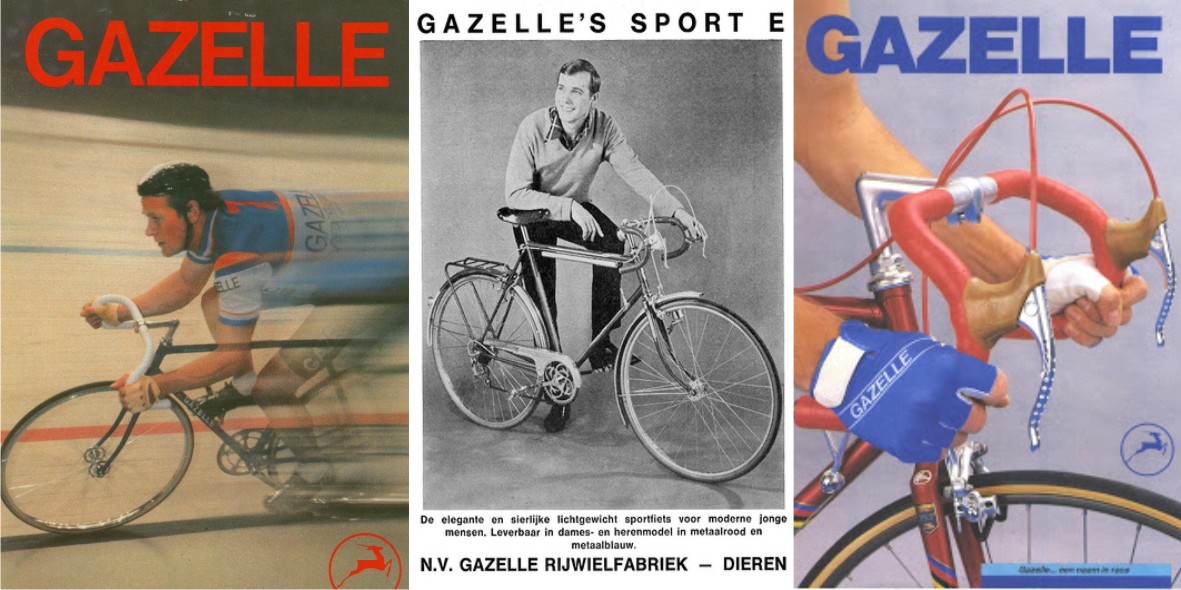

1963

The company merges with Batavus from Heerenveen, but the cooperation did not meet the basic expectations and ended after 2 years. In the mid-1960s Gazelle created

RACE BIKES DEPARTMENT

at the Dieren factory, where skilled craftsmen produced handmade racing frames.

1964

Gazelle was the first Dutch bicycle company to release

FOLDING BIKE

1966

Gazelle releases again

TANDEM

- more modern and lighter. In the same year, a 2-million bicycle is created.

SOLD

2.000.000 BIKES

1968

The company acquires bicycle brands such as Juncker, Simplex and Locomotief as well as the well-known brand Moped Berini.

1971

The company acquires bicycle brands such as Juncker, Simplex and Locomotief as well as the well-known brand Moped Berini.

1980

Gazelle was the first to create

AXLE CRANKS WITH BALL BEARINGS

1987

Tube Investments sells its bicycle department to Derby Cycles Corp. This international corporation based in New York currently owns the Raleigh bicycle brand, the English manufacturer of Sturmey Archer bicycle hubs, as well as well-known German bicycle brands such as Kalkhoff, Rixe, Winora and Staiger. At the time of the company's greatest commercial success (around 1980-85), Gazelle

EMPLOYED 35 PEOPLE

1992

The century of the company coincides with the release

8 MILLION BIKE

On the hundredth anniversary of the creation of Gazelle, Princess Margriet gave the company

TITLE ROYAL

(royal).

1999

The company releases

10,000,000 BIKE!

Gazelle currently

WORKING 550 PEOPLE

Gazelle is one of the few bicycle manufacturers of this size that still builds most of its frames itself. 20% of total production is exported to Belgium and neighboring regions of Germany.

2001

Derby Cycles Corporation due to financial problems sold Gazelle to Dutch investment funds.

ANNUAL PRODUCTION

is currently around

380 THOUSAND ARTS

while Gazelle's market share is around

30% PERCENT

2005

By October 2005, Gazelle had produced a total of

12 MILLION BIKES

and until 2008

ANOTHER MILLION

2010

Gazelle is selected

MOST TRUSTED

A BIKE BRAND IN EUROPE

according to Reader’s Digest Review

2011

Gazelle is taken over by

PON HOLDINGS

co-owner of Caravelo and importer of the Volkswagen brand in the Netherlands.

2014

It's time for a new stage!

In order to create space for further increase in production and development, Gazelle begins another

FACTORY EXTENSION

3.IX.2015

Jego Wysokość

His Majesty

KING WILLEM-ALEXANDER

personally opens a new one

PRODUCTION HALL

with area over

7000 m2

n which modern assembly lines and automated paint shop were located.